Technology is always evolving - and AFC-Holcroft Process Controls/Supervisory Systems are always in step with the latest requirements for data and reporting.

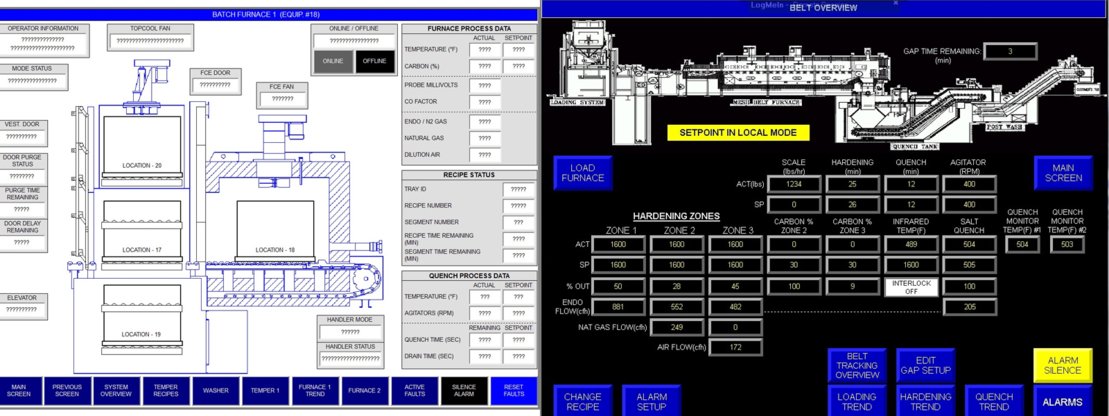

BatchMaster is an individual batch furnace management package, based upon a subset of AFC-Holcroft’s highly successful ProcessMaster™ heat treating supervisory system. The main operator HMI interface is a NEMA 4 industrial panel PC with a full color 15” wide view, LCD touch screen. The HMI communicates to the batch furnace PLC controller. This configuration is used for full operational control and was selected to obtain the communication speed required to obtain reliable transfer of information. The 15” color graphic LCD displays a variety of screens for viewing control loops, setpoints, recipe entry, process trending and other analog and digital status. All process parameters are read every second and recorded every minute. The disk storage will handle 10 years of process data.

Standard:

Optional:

AFC-Holcroft’s BeltMaster™ furnace management system controls the following furnace parameters:

The AFC-Holcroft ProcessMaster™ system is an advanced HMI/SCADA (Human Machine Interface/ Supervisory Control and Data Acquisition) computer software package designed to provide an off-the-shelf solution to most possible configurations of furnace systems. ProcessMaster™, initially released in 1985, has focused solely on the Heat Treat Industry and has developed a product ideally suited to the needs of industry.

ProcessMaster™ provides communication to most process temperature, carbon controllers and furnace PLC’s, data-logging minute by minute all process parameters and alarm history, provide a real time graphic display, provide automatic furnace recipe control, a operator interface and flexible reporting in text or graphic forms.