Metallurgical Processes:

Neutral Hardening, Austempering, Carburizing, Carbonitriding, Normalizing, Annealing, Stress Relieving, Tempering, Solution Treating and Aging

Types of Products:

Stampings, Fasteners, Springs, Forgings, Castings, Valve Lifters, Camshafts and Precision Machined Components

Unique Features:

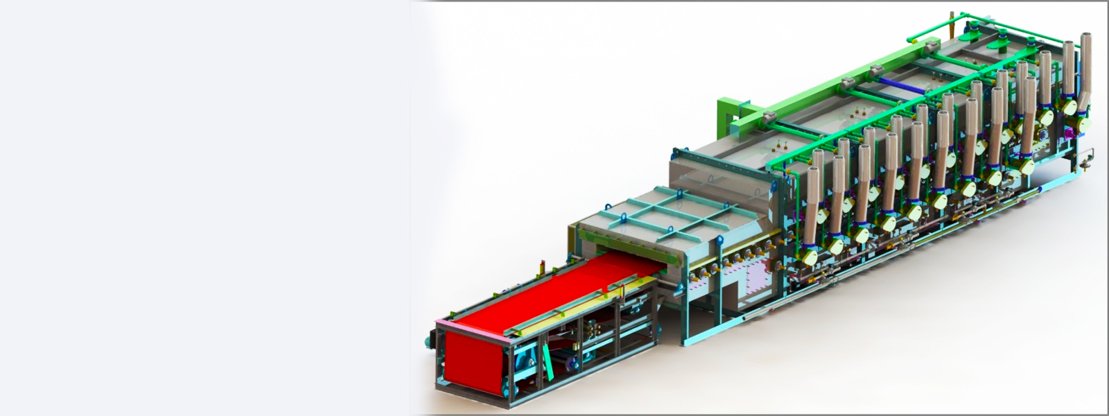

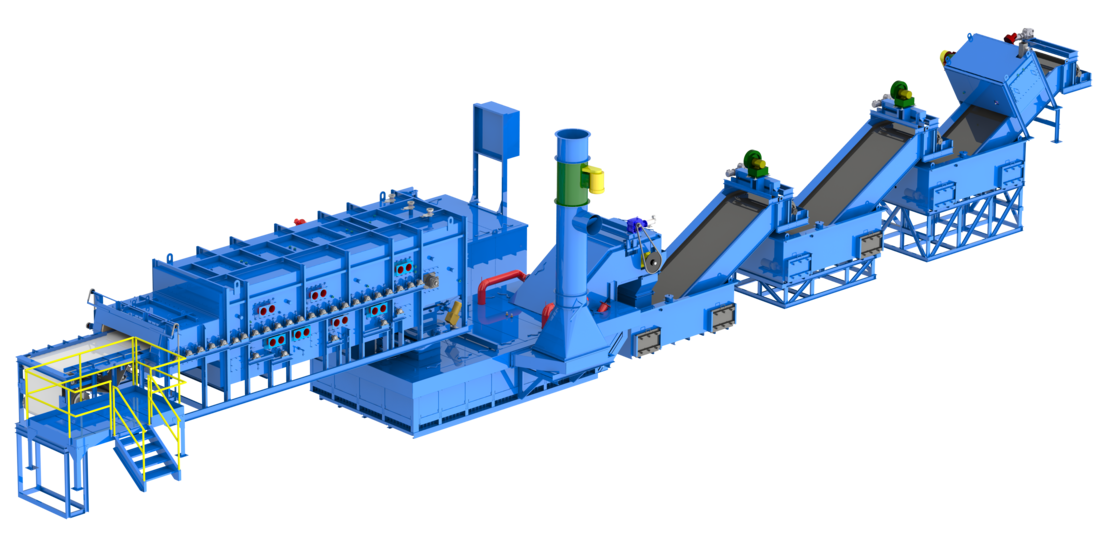

Mesh Belt

(PDF |

783.54 KB |

eng-US )